Why Mobile Robot Software Outweighs Hardware in Today’s AMR Automation Companies

Whether building or buying automation solutions, the question of prioritizing hardware versus software remains a critical decision point for both vendors and customers.

The machine’s hardware components (sensors, actuators, motors, and frames) provide the physical capabilities and boundaries that define what the robot can do. Meanwhile, the robot’s core automation software (the programming that controls those physical components) is what determines how effectively those capabilities are utilized.

Understanding this distinction affects both initial selection criteria and long-term value expectations. So here’s our suggestion: pick the solution from an automation company whose developers own their software stack.

Why? Because:

- Any robotics company can access similar motors, sensors, and components, but proprietary software creates the true competitive advantage; and

- Hardware replacement cycles quickly become expensive and disruptive, while ongoing software updates can deliver new capabilities instantly.

The most valuable AMR robots may not have the most recent motors or the fastest processors – but they absolutely need to have the most intelligent, adaptable, and continuously improving software.

How Software-Oriented Automation Companies Deliver Superior AMR Robots

Software delivers strategic advantages in mobile robot development by enabling flexibility, intelligence, and connectivity that hardware alone cannot match. And while physical components may define baseline capabilities, automation companies that prioritize software development create AMR robots that deliver substantially greater value – with enhanced performance and adaptability.

Software Allows AMR Solutions to Have Ever-Evolving Capabilities

As opposed to single-purpose tech that becomes antiquated after a year of use, automation companies that focus on software are able to keep their mobile robots relevant. They do so with their ability to update their solutions’ programming. In this way, they enable their AMR robots to continuously improve and adapt, without physical upgrades or replacements.

- Capabilities Expand Over Time: AMR solutions built for transport can add inventory scanning and management through remote software updates, without added hardware changes.

- Adaptation to Environments: AMR robots adjust navigation parameters to match each facility’s layout. They perform differently in different places. Software makes this possible.

- Better Responses to Unexpected Situations: Mobile robots learn from experience.Software develops more sophisticated reactions to obstacles based on data from multiple deployments and recovery happens faster.

- Improvements are Spread Across Models: Algorithms developed for more premium, or later released, AMR robots often transfer to basic models, benefitting the entire fleet.

Software Optimizes Existing AMR Hardware Performance

Software efficiency directly affects how any piece of hardware is able to be used. Smart programming can extract more and better performance from the same physical components. And some hardware limitations can even be mitigated through clever software approaches:

- Battery management algorithms can extend runtime by optimizing power use with acceleration control, motor usage patterns, and smart charging schedules, without needing a new battery.

- Task sequencing software can minimize empty travel time, effectively increasing throughput without faster motors.

- Predictive algorithms can offset limited sensor range by anticipating obstacles before detection, holding off the new for new sensors.

- Advanced filtering algorithms extract more information from basic sensors than was previously possible, upgrading perception without physical changes.

Software Compiles Valuable Data Analytics for AMR Automation

Data gathered by software algorithms can be converted into intelligence that improves both immediate operation and long-term planning.

- Route optimization through data. Software analysis might show that your mobile robot fleet could be using paths that are 15% shorter, creating immediate efficiency gains.

- Identification of efficiency gaps. Analysis of AMR operational data can show patterns of usage where time gets wasted, allowing optimization and expense reduction.

- Adaptation to specific conditions. AMR robots from forward-thinking automation companies adjust routes based on time-of-day traffic patterns. They learn from experience.

- Problem detection before failure. Pattern recognition spots unusual vibrations or temperature changes in an AMR robot, allowing maintenance to be performed before breakdowns occur.

- Data-driven development prioritiesUsage patterns might show that improving an AMR robot’s turning speed matters more than straight-line movement. Good automation companies let data guide their roadmaps.

Software Allows Simpler Integration for Mobile Robot Fleets

Since mobile robots must works cohesively with other automation and machines in their environment, successful integration with these technologies is key. Through the software powering your AMR solution, this collaboration can be made significantly less painful and much quicker.

- Coordinated multi-robot workflows. Orchestration algorithms let different AMR robots work together on complex tasks. Teams of robots accomplish what individuals cannot, and automation solutions become more powerful through coordination.

- Open API access. The best automation companies will provide you with API access for their AMR solution functions. This allows your own external systems to control the AMR robots without needing hardware knowledge, making for seamless integration.

- Connection to legacy systems. Software adapters allow new mobile robots to interact with and receive work orders from management systems automatically. This way, your AMR robots become part of your workflow, not separate from it.

But – Mobile Robot Hardware Still Matters

That said, hardware does establish the physical constraints within which software must operate. No amount of programming can make a robot perform physical tasks beyond its mechanical capabilities.

The ideal approach combines capable hardware with exceptional software. When evaluating AMR solutions, look for hardware that meets baseline requirements for your environment, then prioritize software capabilities that maximize that hardware’s effectiveness and future potential.

Software Ownership: The Advantage to Look For in AMR Automation Companies

When selecting a provider for AMR robot deployment, software ownership represents a fundamental advantage that should be considered. An automation company that develops and is an expert in its own software, provide their customers with greater control, faster responses, and more sustainable long-term value than those relying on third-party solutions.

Development Aspect

Companies Using 3rd-Party Software

Companies Using Own Software

Development Timeline Control

Dependent on third-party release schedules

Full control over development pace and feature rollout

Feature Prioritization

Follow vendor roadmaps designed for broad market appeal

Implement customer-specific features based on true usage needs

Hardware-Software Coordination

Separate development cycles with integration challenges

Simultaneous optimization of hardware and software components

Response to Customer Requests

Request submission to vendor, evaluation based on market size

Direct implementation of needed features without external approval

Faster Development Cycles and Integration of AMR Robots

Companies that own their AMR robot software control the entire development process, eliminating 3rd-party dependencies that can delay implementation and adaptation.

- Customer-driven development priorities ensure features that matter most to users get built first. When an automation company owns its software, market needs, not external vendor roadmaps, drive development decisions for mobile robot functionality.

- Simultaneous hardware-software optimization creates AMR robots with software and hardware designed specifically for one another, eliminating challenges that plague multi-vendor solutions and allowing components to be evolved together, with coordinated changes that improve overall AMR robot performance.

- Testing in actual operating environments rather than simulated conditions. Automation companies that control their entire stack can test changes in real customer settings, ensuring solutions work in practice, not just in theory.

- Customer needs drive development directly. If a specific feature is needed, an automation company that owns its software can add it directly without waiting for a third-party vendor’s approval.

Compounding Experience, Resolutions and AMR Knowledge Base

Software ownership creates institutional knowledge that continuously improves the customer experience and product reliability across the entire AMR robot fleet.

- Cross-deployment learning improves all customers’ automation solutions simultaneously. Insights gained from one mobile robot installation immediately benefit others without additional licensing or negotiation.

- Solutions benefit all customer automation solution simultaneously. Insights gained from one mobile robot installation are immediately available to all customers without additional charges.

- Diagnostic capabilities improve with each deployment. Patterns emerge across deployments allowing automation companies that own their software to analyze mobile robot performance across multiple sites and identify issues before they affect your operation.

- Consistent expertise availability ensures that the people who know the automation solution best remain involved throughout its lifecycle. Customers access the actual developers who built the mobile robot software rather than support staff with limited system knowledge.

Ongoing Customer Partnership Instead of One-Time Transaction

Software ownership transforms vendor relationships from simple product purchases to strategic technology partnerships. This allows continuous value to be delivered far beyond the initial sale.

- Operational data becomes a competitive advantage for both vendor and customer. Mobile robots generate valuable usage data that can be analyzed for continuous improvement when there are no data ownership conflicts between multiple vendors.

- Software upgrades preserve existing investments rather than forcing replacement. When automation companies control their software, they ensure new features work with existing hardware whenever possible.

- Custom integration solutions develop for specific customer environments. Companies with full software control can modify their AMR robots to work with unique facility layouts or proprietary systems that third-party vendors would ignore as too niche.

The Bottom Line: Software Determines the True Value of an AMR Automation Company

Software determines how effectively an AMR robot’s hardware performs in real operations. Companies that own their software deliver better results through:

– Continuous updates that add capabilities without hardware changes

– Faster implementation of customer-requested features

– Direct problem resolution without third-party delays

– Seamless integration with existing systems

The difference is especially highlighted when comparing development speed, problem-solving, and ongoing support. Companies using third-party software face constraints in all these areas, while those owning their code can respond directly to customer needs.

At Quasi Robotics, we’ve developed our proprietary Q.AI intelligence software to deliver automation that adapts to changing needs. By maintaining complete ownership over our software, we ensure our solutions expand capabilities, integrate seamlessly with existing systems, and remain relevant for years.

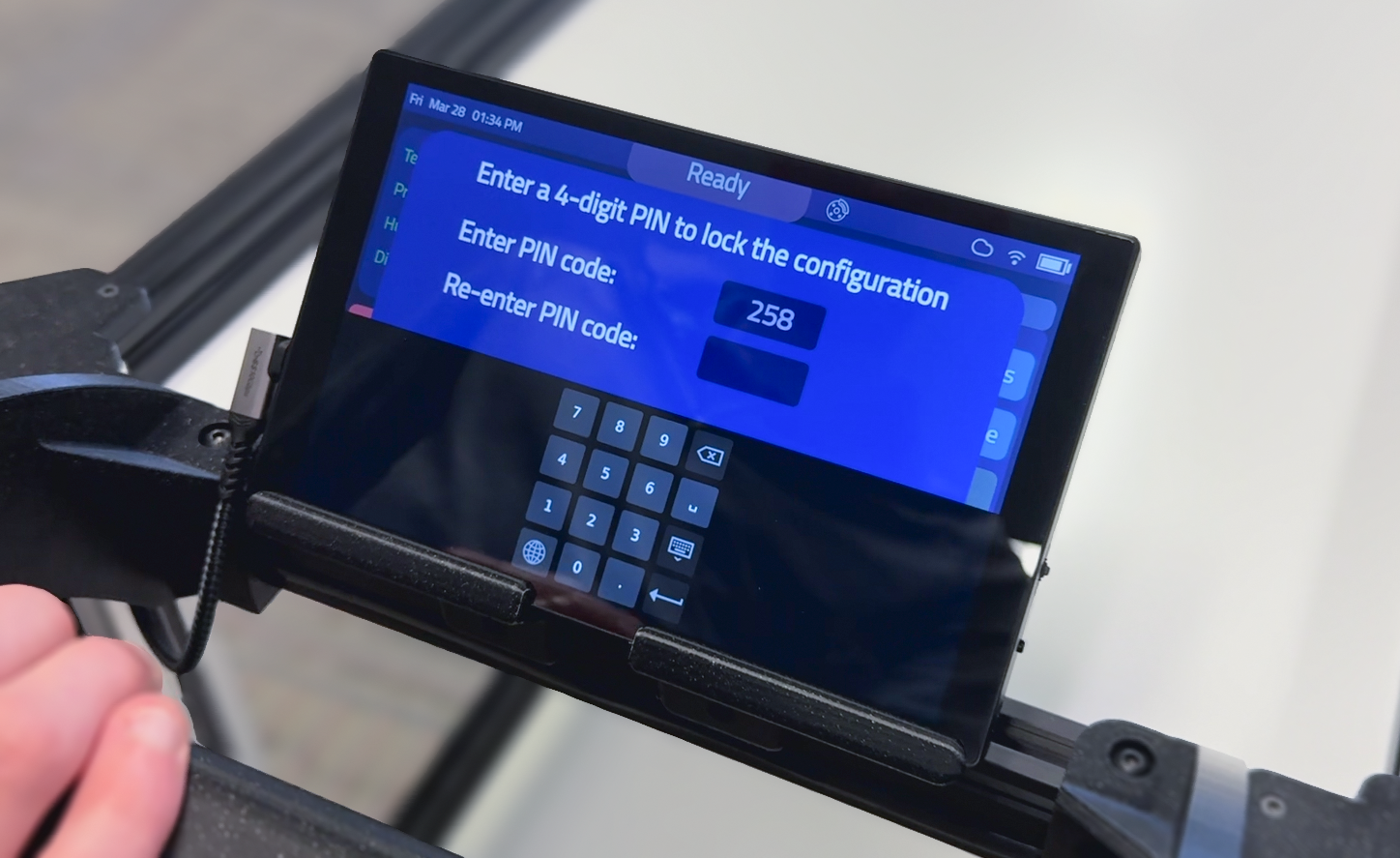

For Model C2 autonomous delivery cart users, this means concrete benefits: increasing capabilities via remote updates, immediate support from the same team that built the system, and data-driven optimization through cloud analytics. The C2 adapts to your specific material transport requirements rather than forcing process changes.

The result is material transport automation that evolves with your business needs instead of becoming outdated.

To learn how the Model C2 and our software-first approach can transform your material movement, visit www.quasi.ai/c2-cart.